Using outside air to reduce natatorium operating costs

Using economizing with indoor pools

While most economizers operate in a similar fashion, those used with indoor pool dehumidifiers have unique requirements. Many basic economizers are not adequately equipped to balance air temperature over time. When the controller senses the outside air is right for cooling, 100 per cent of the return air is exhausted and replaced by an equal amount of outside air. The result can be rapid economizer cooling followed by reheating once the economizer cycle ends and the compressors restart.

Some of today’s technologically advanced dehumidifiers have taken economizers to the next level. Rather than full economizing or full direct-expansion dehumidification, these units control both outdoor and return air using a modulating mixing box to regulate cooling and dehumidification. Both outdoor air and return air can be gradually mixed in varying quantities for optimum occupant conditions. In this case, only the required amount of outdoor air is used to provide the set point conditions at the lowest cost.

By using this method, compressor operation is minimized without sacrificing space conditions. This can also represent lower operating costs over conventional economizers. Further, IAQ is improved because more outside air is used, and compressor wear is lessoned as the system operates less frequently.

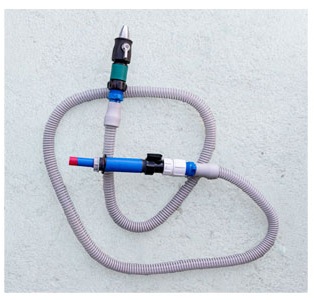

Dehumidifiers using economizer strategies such as this require special design features to operate efficiently. Mixing box, air path, and fan design must be optimized to maximize cooling and dehumidification. High quality sensors also need to be strategically located to carefully monitor temperatures and humidity, while the control system requires specifically designed firmware and software to ensure precise operation.

Improvements in design and components

The indoor pool environment can be highly corrosive, resulting in damage or destruction of critical dehumidifier components such as sensors, dampers, and solenoids. Early indoor pool air-side economizers did not always share the same high regard as conventional HVAC equipment and were destined for failure due to poor design or improper construction. Sensors are a good example of this—especially in the indoor pool environment.

Quite often, sensors were rarely, if at all, calibrated during their lifespan, adding to the control problem. Sensors were often placed in the wrong location, and in some cases the wrong type was used, which further limited economizer performance. Enthalpy sensors, which measure total heat content, cannot differentiate the latent (wet) from the sensible (dry) amount. Knowing the exact latent heat content is crucial since dehumidification is the primary function in a high-moisture indoor pool environment.

Other economizer design flaws include improperly sized dampers which restrict or limit airflow. Pressurization is also critical. Natatoriums, for instance, require a negative pressure to minimize pool odours and humidity from infiltrating adjacent areas in an aquatic facility (e.g. offices, classrooms, etc.). On the other hand, over pressurization will hamper airflow resulting in poor economizer performance.

Some studies have shown by enhancing the operation of an economizer system it can be one of the most cost-effective measures in optimizing energy performance while also assuring a quick return on investment (ROI). Components like sensors have greatly improved, and using industrial-grade sensors can provide even greater accuracy.

Direct-digital controls also improve the performance of an air-side economizer. Today’s developments in hardware and firmware allow precise monitoring and control of outside air.

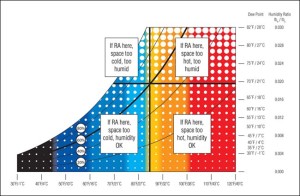

An economizer is an excellent choice for an indoor pool environment for other reasons as well. Since the space set point temperature is typically operated at 29 C (84 F), outside air can be used more frequently and over a wider range of outdoor temperatures than in office applications.

Outside air can also be used for dehumidification and to some degree heating as well. Digital control technology plays a key role in analyzing and comparing outside air temperature and humidity with return air temperature and humidity and deciding which mode offers the lowest cost of operation to meet the set point conditions.