Using outside air to reduce natatorium operating costs

Economizer psychometrics

A prudent indoor pool dehumidification strategy is to use an economizer as the first stage of control and not turn on the compressor system. Since the fans are already running, it makes more sense to simply open the dampers to maintain conditions.

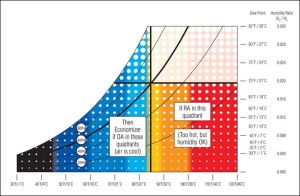

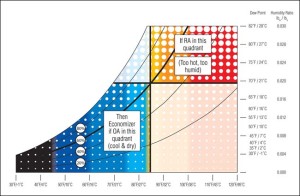

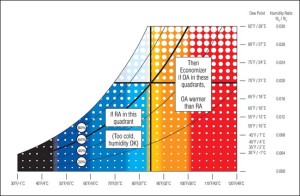

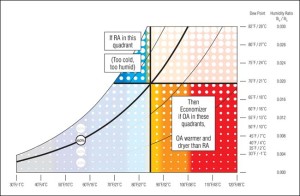

To better understand the pool room environment, the psychrometric chart can be divided by the indoor pool room set points of 29 C (84 F) and 60 per cent relative humidity, the most frequently used setting for indoor pools. A control system can use these two set points to divide the psychrometric chart into quadrants along the vertical 29 C (84 F) dry bulb axis line and the horizontal absolute humidity line of 21 C (70 F), dew point at 29 C (84 F) and 60 per cent relative humidity. The goal is to have the controller compare the condition of the return air to the set point quadrants on the psychrometric chart. The controls will determine if the space requires heating, cooling, and/or dehumidification depending on which quadrant the return air dry bulb and dew point temperatures are.

Cooling economizer

In this mode, the return air condition is in the bottom right quadrant, meaning the air is too hot, but humidity is acceptable. If the outside air is in either the upper left or lower left quadrants (outside air is cooler than return air), then the controller should slowly open the outside and exhaust air dampers and close the recirculation damper to introduce up to 100 per cent cool outside air into the indoor pool space.

Cooling and dehumidification economizer

In cooling and dehumidification economizer mode, the return air condition is in the upper right quadrant indicating the air is too hot and too humid. If the outside air is in the lower left quadrant (outside air is cooler and dryer than return air), then the controller should slowly open the outside and exhaust air dampers and close the recirculation damper to introduce up to100 per cent cool outside air into the space.

Heating economizer

To use the heating economizer, the return air condition is in the bottom left quadrant where the return air is too cold and humidity is acceptable. If the outside air is in either the upper right or lower right quadrants, where the outside air is warmer than return air, then the controller should slowly modulate open the outside and exhaust air dampers and modulate closed the recirculation damper to introduce up to 100 per cent warm outside air into the space.

Heating and dehumidifying economizer

To use the heating and dehumidifying economizer, the return air condition is in the upper left quadrant where it is too cold and too humid. If the outside air is in the lower right quadrant it is warmer and dryer than return air. Under these conditions, the controller should slowly modulate open the outside and exhaust air dampers and modulate closed the recirculation damper to introduce up to 100 per cent warm outside air into the space. The controller should check if the outside air is cooler than the return air, but is not quite as concerned if the humidity is somewhat higher.

How to save additional energy during the heating cycle

The economizer function can also be used in other ways to lower operating costs. By using an economizer in conjunction with the heat recovery mode of the dehumidification system, heating costs can be further reduced. Indoor pools typically have high heating demands, and the heat pump operation of the dehumidification stage can satisfy much of these requirements.

When the refrigeration loop is running in the heat recovery mode, and the space is calling for heat, the air passing over the evaporator is being cooled to saturation. The sophisticated direct digital control system measures and compares the condition of air leaving the evaporator with the outside air temperature and humidity. If the outside air is warmer and dryer than the exhausted evaporator air, the control system will automatically close the recirculation damper and fully open the exhaust and outside air dampers. All of the cool, saturated air coming off the evaporator coil is exhausted and replaced with 100 per cent of the dryer, warmer outside air. The outside air is then passed over the heat recovery hot gas reheat condenser coil where this supply air is reheated with ‘free’ sensible and latent return air heat, which was recovered in the evaporator prior to being exhausted.