Using outside air to reduce natatorium operating costs

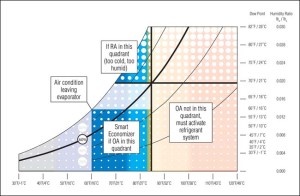

By using this system, a significant amount of energy is saved, which can also be used for pool water heating whenever the space temperature is satisfied. Even though the compressors are operating, these economizers can save between $2000 to $4000 per year in heating energy that standard economizer mixing boxes cannot. This economizing method is only possible if the pool dehumidifier has a mixing box, the exhaust air damper is located downstream of the evaporator and upstream of the hot gas reheat condenser coil, and is equipped with control software that knows what action to take when the proper energy-saving conditions occur.

Other ways to maximize indoor air quality

Beyond humidity and temperature, a major factor in IAQ is airborne pollution that off-gasses from the pool and wet deck. The concept of ‘solution by dilution’ has prevailed as the best practice for handling natatorium IAQ. There are dozens of airborne disinfection byproducts, generally referred to as chloramines, and studies have proven they (along with other pollutants) are not only harmful to bather health, but are also corrosive.

Within the last five years, the paradigm has shifted to a targeted intelligent ventilation technique called evacuator source capture. While introducing additional outside air serves many benefits, it can also be costly when brought in excessively to dilute chloramines alone. This is important when outside conditions limit the use of an economizer and outside air.

Technology such as evacuator source capture equipment provides effective exhaust of the worst air in the room, without the need for additional outside air. Effective capture of airborne chloramines can ease the burden on the dehumidification system because it can reduce—if not prevent—the recirculation of corrosive air through the mechanical system. This can extend the life of the building and equipment, while also ensuring the supply air to the natatorium is clean and free of harmful chloramines.

It is important to note the environmental control system (pool dehumidifier) exhaust air function be synchronized with the evacuator. As the evacuator’s exhaust air increases or decreases, the dehumidifier changes simultaneously in the opposite direction to balance outdoor air requirements.

Periodic maintenance ensures peak performance

Economizer systems are often neglected and, over time, can degrade to the point they do not operate correctly, resulting in wasted energy. Therefore, periodic maintenance ensures these systems run efficiently.

Economizers, regardless if installed on a pool dehumidifier or conventional HVAC unit, will perform more efficiently if properly inspected and calibrated. Starting with dampers, be sure they are not seizing, a common problem with corrosive environments like indoor pools and saltwater locations. Further, be sure actuators are adjusted for full closure and linkages are not binding. Improperly positioned dampers can significantly reduce the efficiency of the system due to increased mechanical cooling or heating load because the system is operating with incorrect outside air, return air, and exhaust airflows.

Finally, inspect the unit’s blade and seals for leaks, which can account for as much as 10 per cent of rated damper airflow. Keep the return air and outside air sensors calibrated as they are critical in determining the economizer operating mode.

Are indoor pool economizers cost effective?

The true test of an economizer is its ability to track system operation over a meaningful time period. This way, modelling data can be used to accurately predict energy savings. Accurate representation requires hourly analysis of internal loads along with outside environmental conditions. Instantaneous cooling, heating and/or dehumidification load for each hour along with the simultaneous external conditions must be known.

In summary, air-side economizers are a good investment for reducing operating costs. Before purchasing new dehumidification equipment, be sure the economizer system will maximize energy savings over a wide range of operating conditions.

Tom Scozzari, B.Sc., is a 30-year veteran of the heating, ventilation, and air conditioning (HVAC) industry and has worked at every level of the supply chain since graduating from the University of Massachusetts with a bachelor of science in mechanical engineering. He can be reached via e-mail at tscozzari@poolpak.com.

Tom Scozzari, B.Sc., is a 30-year veteran of the heating, ventilation, and air conditioning (HVAC) industry and has worked at every level of the supply chain since graduating from the University of Massachusetts with a bachelor of science in mechanical engineering. He can be reached via e-mail at tscozzari@poolpak.com.