Rise to the challenge

Most of the challenge rested on the manufacturer, which sent factory production experts to the site to measure the shells, components, various piping connections, positions of inlets/outlets, and the 11.7- and 7.1-m3/s (25,000- and 15,000-cfm) blowers. The latter were retained and reconditioned to value-engineer project costs. Matching the evaporator coils was the most difficult challenge.

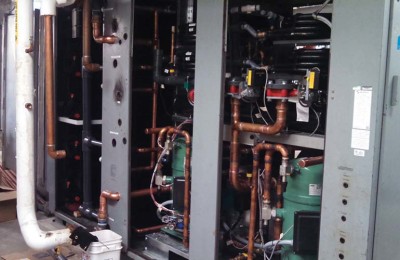

Factory engineers then designed the entire configuration and provided the installing contractor with 3-D, computer-modelled blueprints to simplify on-site assembly and installation. The new partially assembled internal component packages arrived as a compressor/refrigeration circuit skid, separate fully dipped enamel corrosion-resistant evaporator, reheat and hot water coils, microprocessor controller/electrical control panels, and dry coolers to minimize on-site assembly.

“All dehumidifier manufacturers have a similar physical airflow sequence consisting of an evaporator coil, reheat coils, compressor module/refrigeration circuit and fans, but fitting equipment into another manufacturer’s configuration and making it easy for the contractor to install was a custom-engineering feat,” says Bruce Svec, a sales engineer with manufacturer’s rep Imbert Corp., who helped co-ordinate the project.

The new dehumidifier also includes modern technology that enhances the school district’s ambitious green mission. Instead of a conventional 100 per cent refrigerant dehumidifier, two models were installed, which together substitute nearly 544 kg (1200 lbs) of the original systems’ refrigerant by using glycol, an environmentally friendly alternative. The glycol is supplied via polyvinyl chloride (PVC) piping to rooftop dry coolers 18 m (60 ft) away for heat rejection. The units also use a substantially reduced charge of approximately 181 kg (400 lbs)

of R-410A, an environmentally friendly refrigerant which does not have ozone-depleting chemicals such as chlorine.

According to Michelini, there is a noticeable difference between the old and new technology in terms of air comfort, especially in the 240-seat spectator section during swim meets.

Sustainability efforts payoff

The school’s ongoing progressive sustainability efforts, such as high-efficiency pumps, condensing boilers, and various lighting and plumbing upgrades, for example, have led to the district’s Leadership in Environmental and Energy Design (LEED®) Gold certification.

“Reducing refrigerant and chemical use in the school’s dehumidification system is part of our sustainability mission,” says Michelini.

Besides refrigerant reduction, the new dehumidifiers also save 15 to 20 per cent more energy than their predecessors via scroll compressors, direct-drive fans and other comparably higher efficiency components. Besides sustaining a 50 per cent relative humidity, the units use energy recovery to heat the pool water to 26.6 C (80 F), as well as maintain indoor temperatures at 27.7 C (82 F).

Also lending to the project’s success was the pool did not need to be closed during the three-month retrofit. One unit operated continually while the other was installed. Thus, the pool, which hosts important state swimming events, remained operational during its typical 16-hour days.

It was suspected the original dehumidifiers may have unknowingly experienced slowly degrading inefficiencies in between routine annual service checkups. The new dehumidifiers will never run inefficiently because they are equipped with an onboard microprocessor and Ethernet connection that relays more than 100 operating parameters for review to the factory or the end-user’s authorized personnel or service contractor via smartphone or personal computer.

An operating inefficiency can be pinpointed and corrected the day it occurs, rather than discovered months later during a semi-annual service call. The operational data log history can be used by factory engineers to help local contractors troubleshoot and repair service issues.

Indoor swimming pools rooms create their own environment and can be be a big problem when trying to control mold, mildew and dampness. That’s why you need an excellent ventilation and / or dehumidification system. This is something that home owners overlook the seriousness of when thinking of building an indoor pool.